A Comprehensive Guide to Marine Boiler Mountings

The marine boiler, one of the most fundamental pieces of machinery aboard a ship, is responsible for generating steam used for propulsion and other onboard systems. With the evolution of shipping technology, boilers have undergone several advancements, making them safer and more efficient.

Today, boilers on ships are equipped with various essential fittings, known as boiler mountings, which ensure their safe operation.

In this blog, we delve into the most important marine boiler mountings and explain how they contribute to the overall safety and functionality of the boiler.

Essential Marine Boiler Mountings

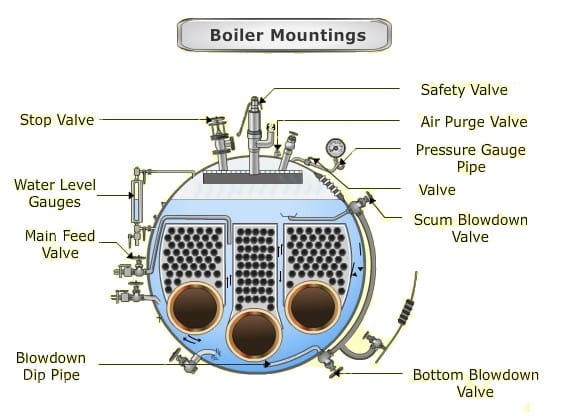

Here’s a comprehensive list of boiler mountings essential for safe and efficient boiler operation:

- Safety Valves

- Water Level Indicators

- Water Level Controller

- Water Level Alarms & Cut-Out Assembly

- Remote Water Level Transmitter

- Main Steam Outlet Valve

- Pressure Gauge & Pressure Switches

- Feed Water Valves

- Burner Assembly

- Air Vent

- Water Sampling Valve

- Manholes, Mudholes & Peepholes

- Bottom Blowdown Valve

- Defoaming (Scum) Valve

- Furnace Drain Valve

- Soot Blowers

- Steam Stop Valve

- Feed Check Valves

- Water Level Gauges

- Air Purge Valve

- Pressure Gauge Valve

- Scum Blowdown Valve

Below, we explain some of these critical boiler mountings in more detail:

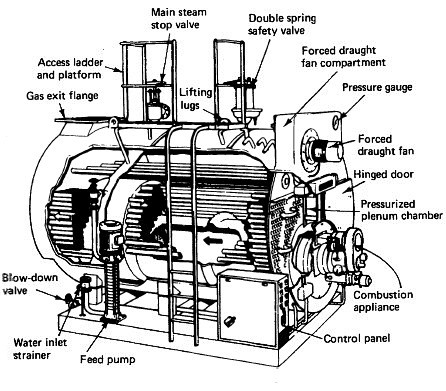

1) Safety Valves

The Safety Valve is one of the most crucial components in a boiler system. Its primary function is to protect the boiler from overpressure conditions. Typically, two or three safety valves are fitted to each boiler: two on the steam drum and one on the superheater outlet header.

The superheater valve is designed to lift first, ensuring a continuous flow of steam through the superheater, even under blow-off conditions. These valves are preset by certified authorities to ensure they activate at the correct pressure and prevent any manual tampering.

2) Main Steam Stop Valve

The Main Steam Stop Valve is mounted on the superheater outlet header and is responsible for isolating the boiler from the steam system. In cases where multiple boilers are connected to a common steam line, the main stop valve ensures that steam from other boilers does not enter a damaged boiler, particularly in the event of a pressure drop caused by a burst tube.

Some main stop valves come with automatic closing devices for emergency situations, preventing steam from flowing to critical systems like the main turbines.

3) Auxiliary Steam Stop Valve

This valve is a smaller version of the main stop valve, designed to isolate the boiler from the auxiliary steam lines. The Auxiliary Steam Stop Valve is also of the screw-down, non-return type and prevents steam from flowing back into the boiler in case of a system failure.

4) Feed Check Valves

The Feed Check Valve regulates the entry of feed water into the boiler. It is a non-return valve, preventing boiler water from flowing back into the feed line in the event of a feedwater supply failure. Both main and auxiliary feed checks are fitted, with the main check valve positioned in a convenient location for operation. A clear indication of the valve’s open and closed status ensures safe operation.

5) Boiler Feed Water Regulator

Maintaining an appropriate water level in the boiler is critical for preventing overheating and ensuring efficient steam production. The Boiler Feed Water Regulator automatically controls the water flow into the boiler, maintaining the desired water level. It is typically installed in the feed line before the main feed check and operates via a float or thermal mechanism.

In modern water-tube boilers with a high evaporation rate, automatic feedwater regulators are mandatory as they prevent dangerous water-level fluctuations.

6) Water Level Indicators

Boilers are required to have at least two Water Level Indicators fitted on the steam drum. These indicators are essential for monitoring the water level in the boiler, ensuring safe operation.

In addition to the direct reading gauges, remote reading indicators may be installed in the control room for convenience.

7) Low Water Alarm

To prevent potential boiler damage caused by low water levels, Low Water Alarms are installed. These alarms are activated when the water level falls below a set threshold, alerting the crew to a potential problem. In many cases, these alarms are steam or electrically operated, and some systems include high-water alarms as well.