Understanding the Cylinder Events in Four-Stroke and Two-Stroke Diesel Engines

Diesel engines play a critical role in marine, automotive, and industrial applications due to their efficiency, power output, and durability. Whether in a massive marine engine or a compact generator, the operation of a diesel engine relies on a sequence of events that occur within its cylinders.

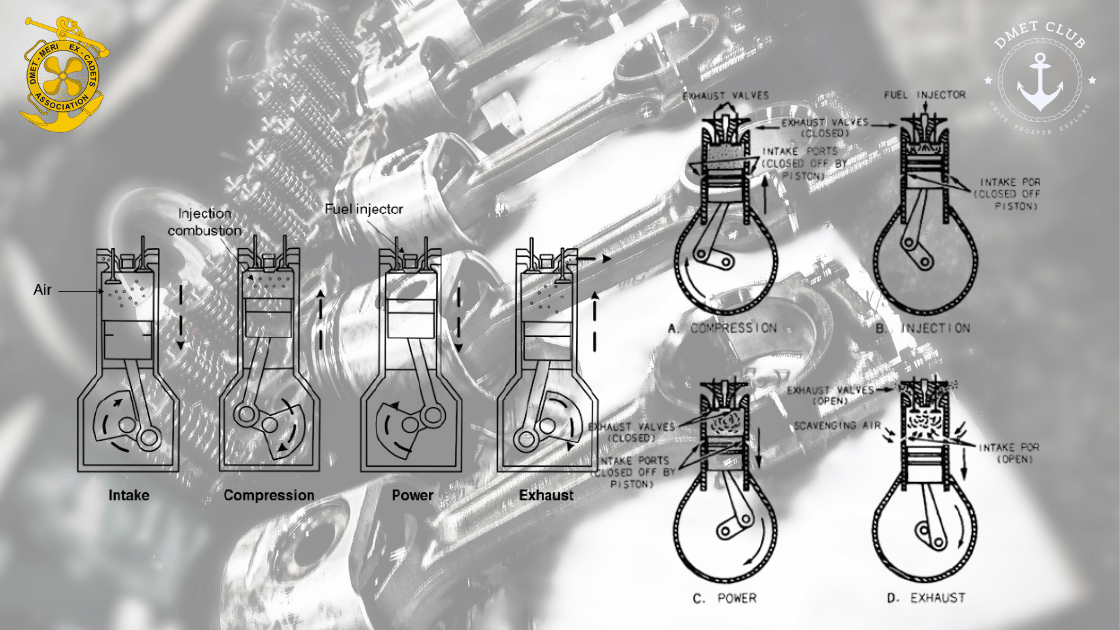

These events vary slightly depending on whether the engine follows a four-stroke or two-stroke operating cycle.

This blog explores, in depth, the sequence of events that occur in both four-stroke and two-stroke diesel engine cylinders — presenting the science behind their mechanics and how each system achieves efficient power generation.

🔧 Fundamental Requirements of a Diesel Engine

For any diesel engine to operate efficiently, five essential processes must take place:

- Supply of air

- Compression of air to increase temperature high enough to initiate fuel combustion

- Injection of fuel into the hot compressed air

- Expansion of hot, high-pressure gases to push the piston and produce power

- Exhaust, or removal of combustion products from the cylinder

Source: Youtube

⚙️ Four-Stroke Cycle Diesel Engine

A four-stroke engine uses two valves (an inlet and an exhaust valve) operated by a camshaft. The cycle comprises four distinct strokes:

1️⃣ Intake Stroke

- The cycle begins with the piston at Top Dead Centre (TDC).

- The air inlet valve opens, and the piston moves downward.

- This downward movement reduces cylinder pressure, drawing fresh air into the combustion chamber.

- The high-velocity air entering through the inlet gains kinetic energy, known as the ram effect, which keeps the valve open even after the piston passes Bottom Dead Centre (BDC).

- The inlet valve closes after the crank has moved 20° to 40° past BDC, once the kinetic energy is dissipated and airflow ceases.

2️⃣ Compression Stroke

- The piston moves upward, compressing the air within the cylinder.

- Depending on the engine design and speed, air pressure can range between 24 and 63 bars.

- Fuel injection begins between 25° and 10° before TDC, initiating combustion shortly after.

- Combustion continues as the piston moves past TDC, ensuring maximum pressure build-up.

3️⃣ Power (Expansion) Stroke

- The combustion generates high-pressure gases (between 54 and 108 bars), which force the piston downward.

- This movement rotates the crankshaft, delivering useful mechanical power.

- As the piston nears BDC, the exhaust valve begins to open—typically at 50° to 40° before BDC—to initiate the blow-down period, during which the exhaust gases begin escaping.

- The pressure inside the cylinder at this point reduces to around 3 to 4 bars.

4️⃣ Exhaust Stroke

- The piston moves upward once more, expelling the remaining exhaust gases through the now fully open exhaust valve.

- Because the valve is wide open, resistance to gas flow is minimal, allowing for efficient scavenging of combustion by-products.

- Before the piston reaches TDC again, the air inlet valve starts to open, setting up the cylinder for the next cycle.

Note 1: Work is only performed during the expansion stroke. The intake and exhaust strokes consume energy, often sourced from the flywheel or other cylinders, resulting in pumping losses.

Note 2: The movement of valves is not instantaneous. There is a time lapse between the valve's initial opening and when it reaches its fully open position — this is governed by the design of the cam profile and the acceleration imparted to the valve.

⚙️ Two-Stroke Cycle Diesel Engine

Source: Youtube

Unlike the four-stroke engine, the two-stroke engine completes all five key processes in just two strokes — meaning every single revolution of the crankshaft generates a power stroke. It achieves this with the help of ports (not valves) and scavenger air, a low-pressure airflow system.

🔄 Combined Exhaust and Intake Stroke

- As the crank rotates from 45° to 40° before BDC, the piston uncovers the exhaust ports, releasing combustion gases into the exhaust manifold (blow-down phase).

- Simultaneously or shortly after, the piston uncovers the scavenger ports at around 35° before BDC.

- Scavenger air, supplied at a pressure of 0.06 to 0.25 bars, enters the cylinder and pushes out residual exhaust gases — a process essential for cylinder cleaning and fresh air charging.

- The scavenger air supply is cut off around 35° past BDC, after which both ports start getting covered by the upward-moving piston.