Understanding the Oily Water Separator: Construction, Working, and Maintenance

One of the most significant concerns for a seafarer or shipowner is the risk of oil pollution accidents. Onboard a merchant vessel, the daily operations generate a mixture of oil and water, which must be properly separated before discharging the treated water overboard. This process is critical in preventing oil pollution, and compliance with international regulations is mandatory.

The regulations governing this process are covered under MARPOL ANNEX I, and it is now a requirement for all ships to have an oil discharge monitoring and control system.

For a ship engineer, understanding the OWS is crucial, as it is one of the most inspected pieces of machinery by Port State Control (PSC) officers and surveyors.

Throughout a career, engineers may encounter numerous makes and models of OWS, making it imperative to understand their working, maintenance, and regulatory compliance.

Function of the Oily Water Separator

As its name suggests, the Oily Water Separator is designed to separate oil from water in the bilges of a ship’s engine room, cargo holds, and other oil-contaminated areas. According to maritime regulations, the oil content in water processed by the OWS must not exceed 15 ppm before being discharged overboard.

MARPOL Regulations Governing Oily Water Discharge

Under Annex I of MARPOL, Regulation 4 outlines the conditions under which oil mixtures can be discharged:

- The ship must be en route – discharge is only allowed when the vessel is moving.

- Processing through the OWS – the oily mixture must pass through the OWS, which meets the regulatory standards set in Regulation 14 of Annex I.

- Oil content limit – the discharge must not exceed 15 ppm of oil content.

- Exclusion of cargo areas – oily mixtures originating from cargo pump-room bilges on oil tankers are prohibited from discharge.

- Segregation from cargo residues – in oil tankers, the oily water mixture must not be mixed with oil cargo residues.

Ships operating in Antarctic waters are strictly prohibited from discharging any oily mixtures.

Key Requirements for Oily Water Separator (OWS)

According to MEPC 107(49), the OWS must comply with several important standards:

- The Oil Content Monitor (OCM) must be tamper-proof and certified by an authorised organisation.

- The OCM should sound an alarm and record data if the oil content exceeds 15 ppm or if freshwater is used for cleaning.

- The OWS must achieve the regulatory discharge limit of 15 ppm.

- Sensors and alarms must be placed in locations that cannot be easily accessed or tampered with.

- Only trained officers, under the direct supervision of the Chief Engineer, are authorized to operate the OWS. When not in use, the system must be locked to prevent unauthorized access.

Sailing without a functional OWS is illegal, and ships must carry appropriate spares for maintenance.

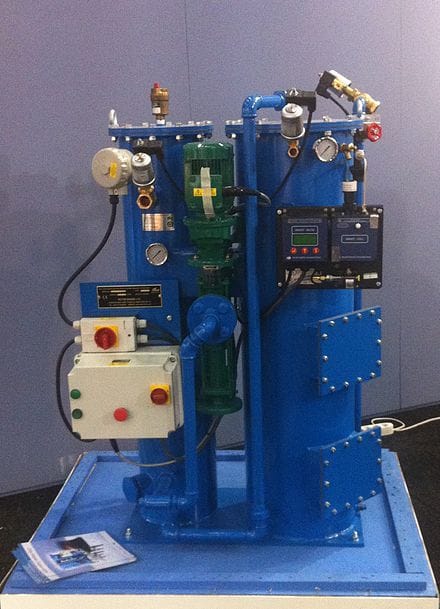

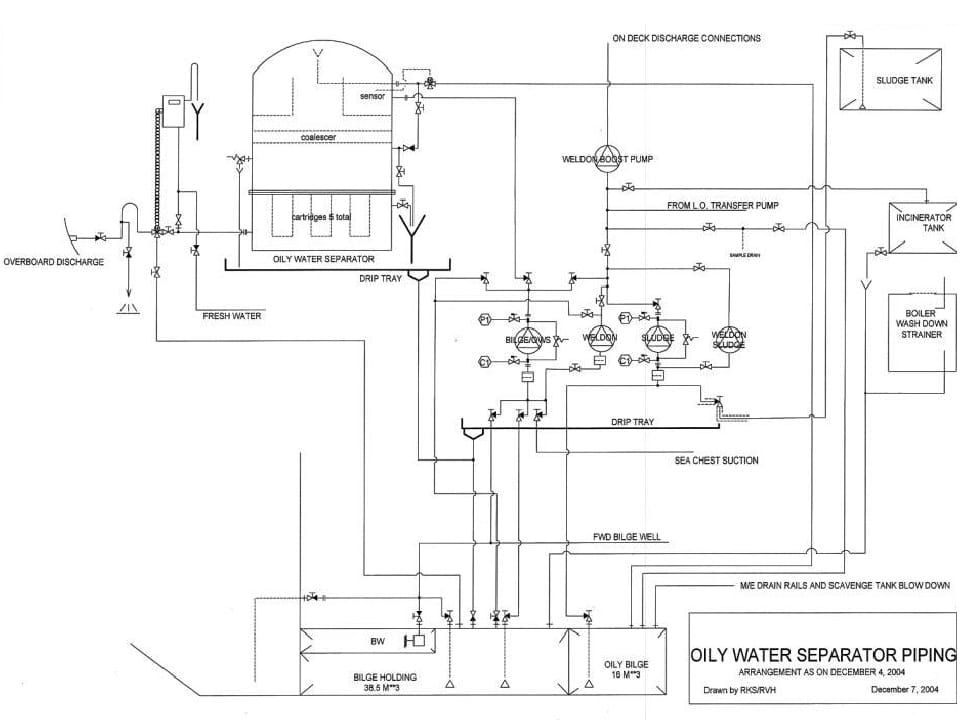

Construction and Working of Oily Water Separator (OWS)

The OWS is typically composed of three main components:

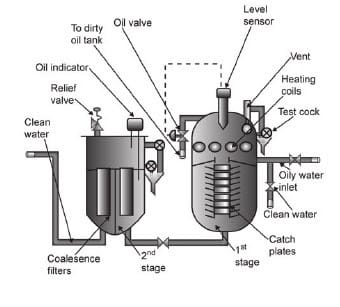

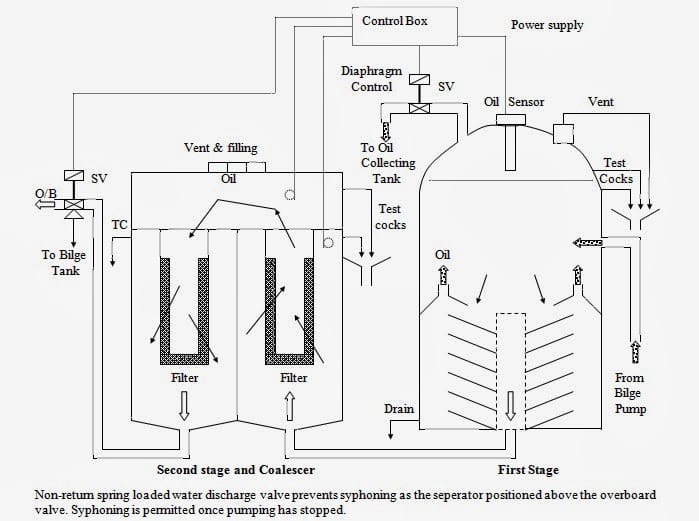

1. Separator Unit

The first stage of the OWS includes a separator unit with catch plates housed in a coarse separating compartment and an oil collection chamber. Due to the lower density of oil compared to water, oil rises to the top and is collected in the oil chamber. The remaining mixture settles in a fine settling compartment, where further separation occurs.

The water discharged from this unit still contains around 100 ppm of oil. A control valve (either pneumatic or electronic) directs the separated oil to the sludge tank. Heaters are often incorporated to facilitate the separation process, especially in colder environments.

2. Filter Unit

The second stage is the filter unit, which processes the discharge from the separator unit. This stage involves:

- A filtration stage that removes particulates.

- A coalescer stage, where small oil droplets combine into larger droplets, making it easier for them to separate from the water.

- A collection chamber, where oil rises to the top for removal.

The water leaving the filter unit must contain less than 15 ppm of oil. If the oil content exceeds this limit, the filters must be cleaned or replaced. A freshwater inlet is provided to flush the filters before and after operation.

3. Oil Content Monitor and Control Unit

The final stage is the Oil Content Monitor (OCM) and Control Unit, which continuously monitors the oil content in the discharge. If the oil content exceeds 15 ppm, the OCM triggers an alarm and shuts off the overboard discharge by activating a three-way solenoid valve.

This valve has two outlets – one leading overboard and the other to the sludge tank. When the OCM detects high oil content, the discharge is redirected to the sludge tank. A freshwater flushing system is provided to clean the OCM unit.